Tempest Filter

- Description

-

Details

Innovative Polisher For Ponds

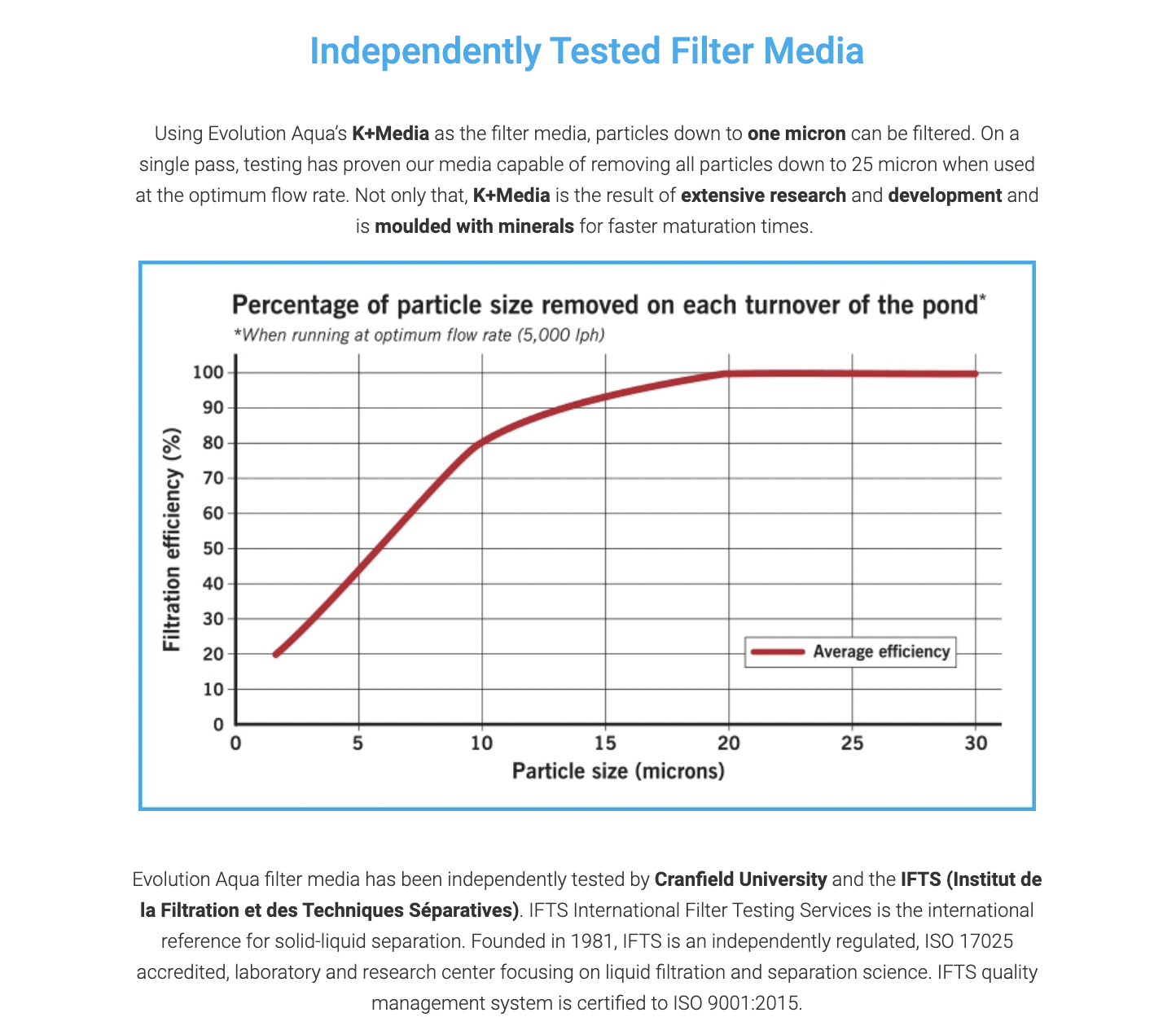

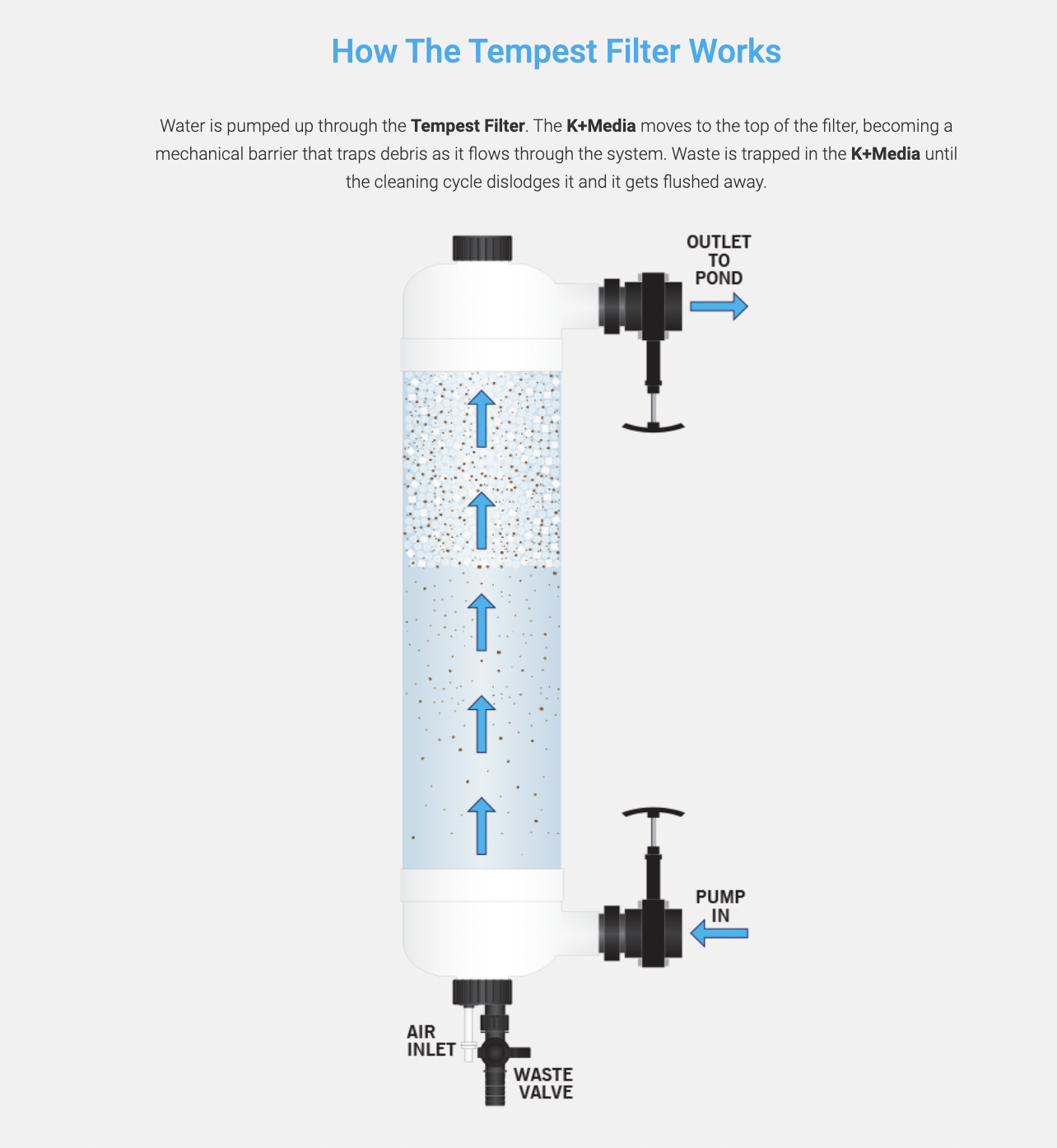

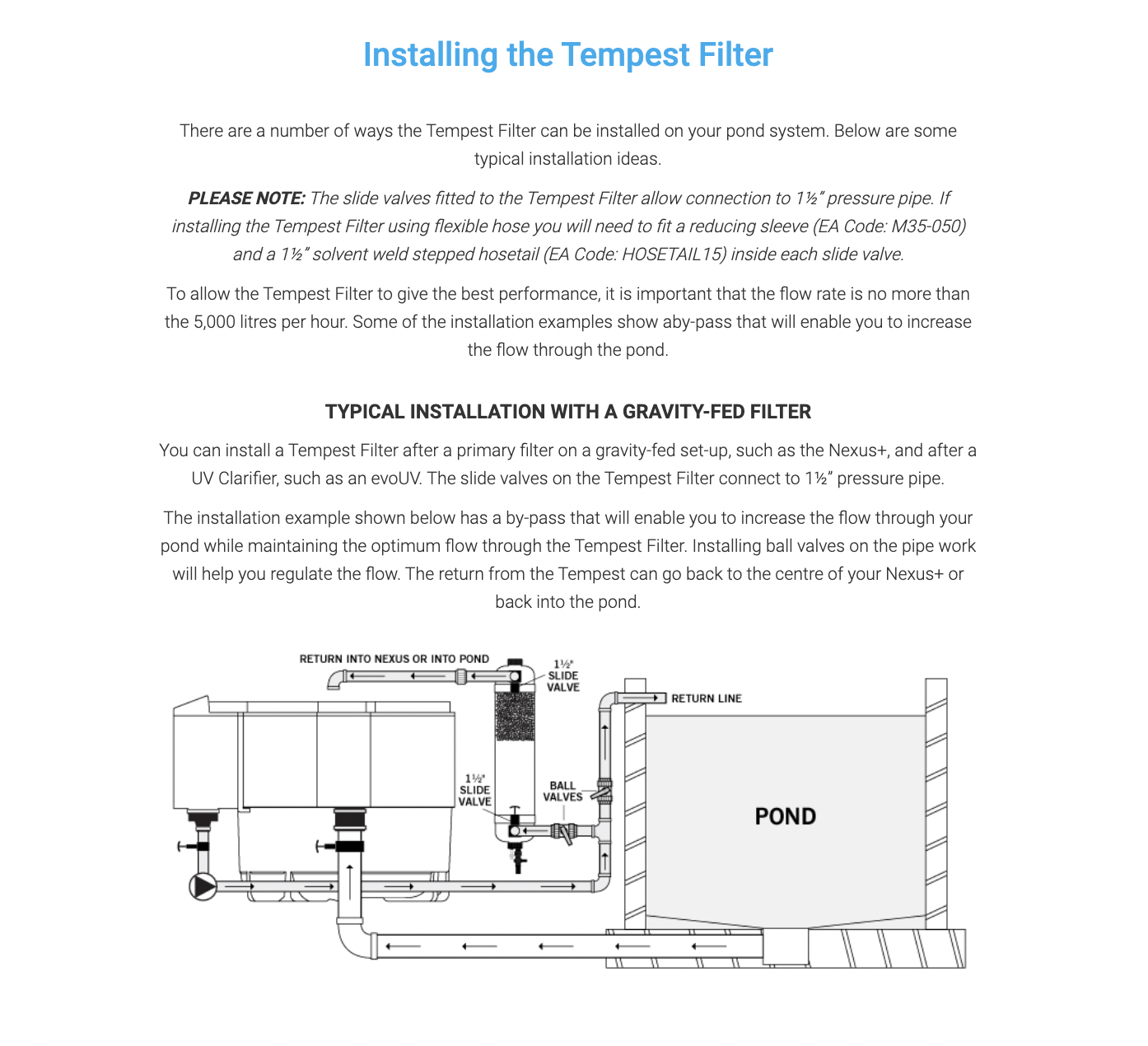

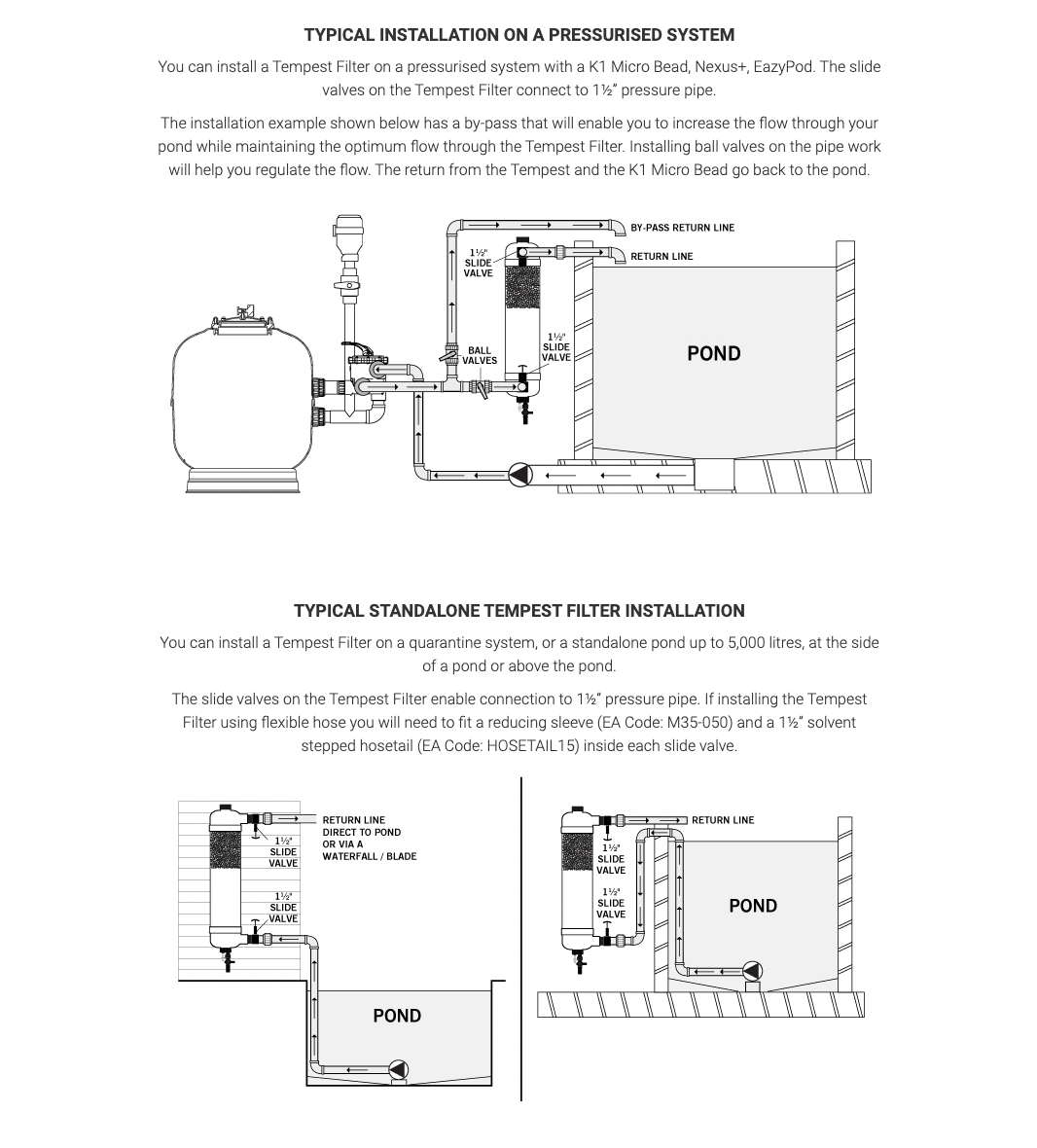

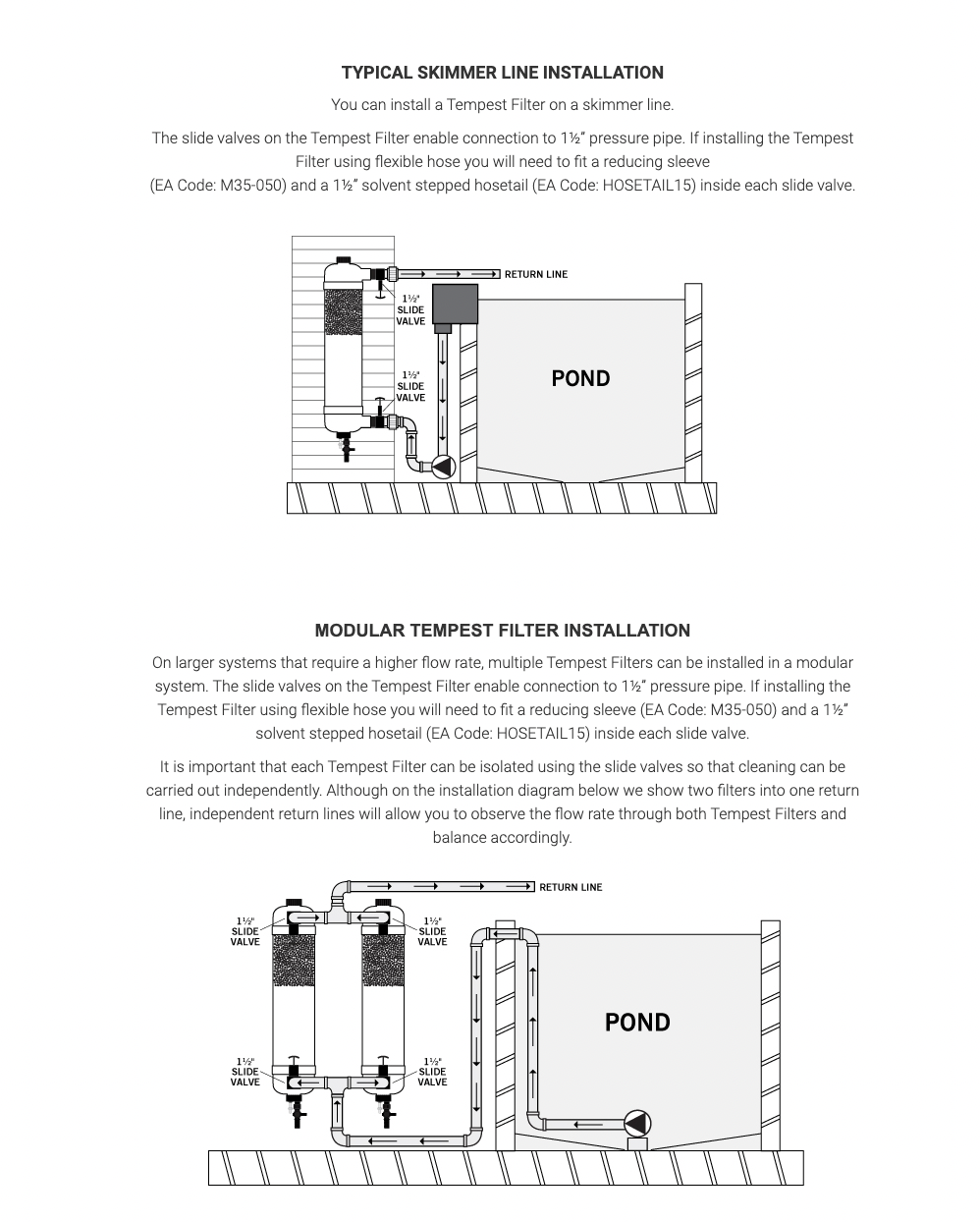

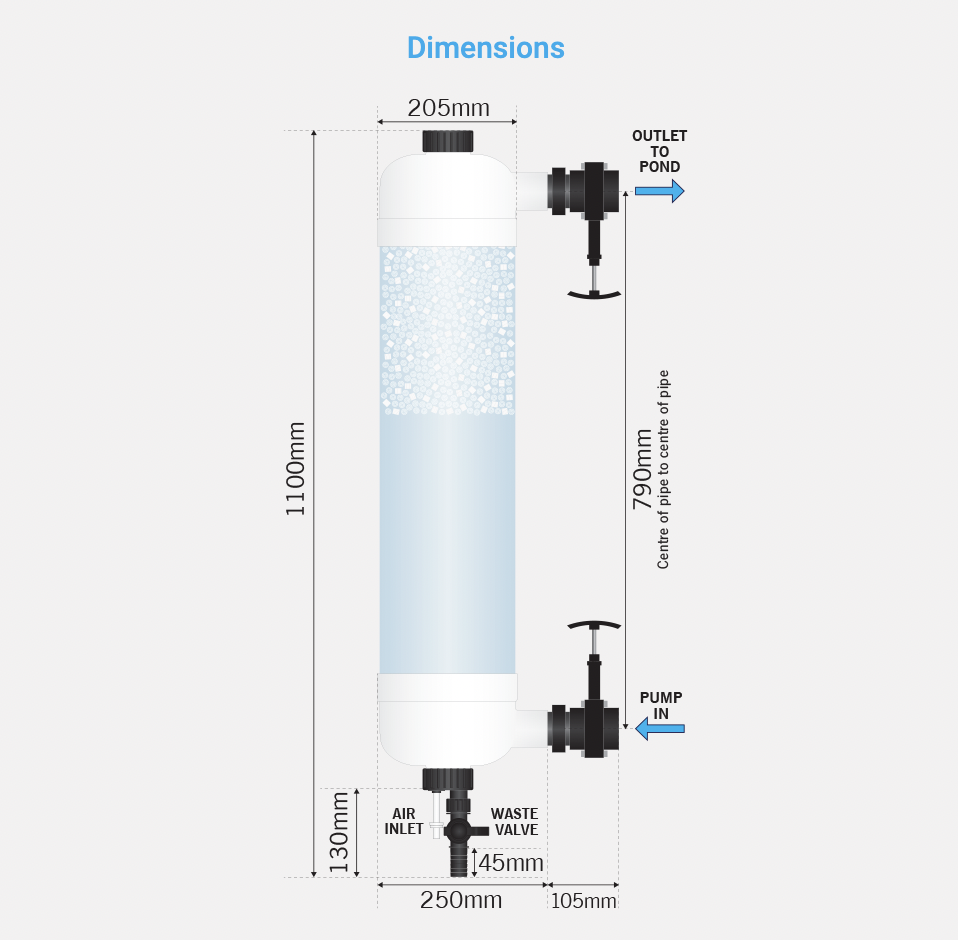

The NEW Tempest Filter is an innovative polishing system for ponds. The Tempest Filter uses our latest filtration media, K+Media, to deliver crystal clear, healthy water.Designed to be used in conjunction with any filtration system, the Tempest Filter offers additional mechanical and biological filtration. The Tempest Filter can be installed on a variety of set-ups and can be used on quarantine systems or as a standalone filter on smaller ponds up to 5,000 Litres / 1,100 Gallons.

Patent Pending Design

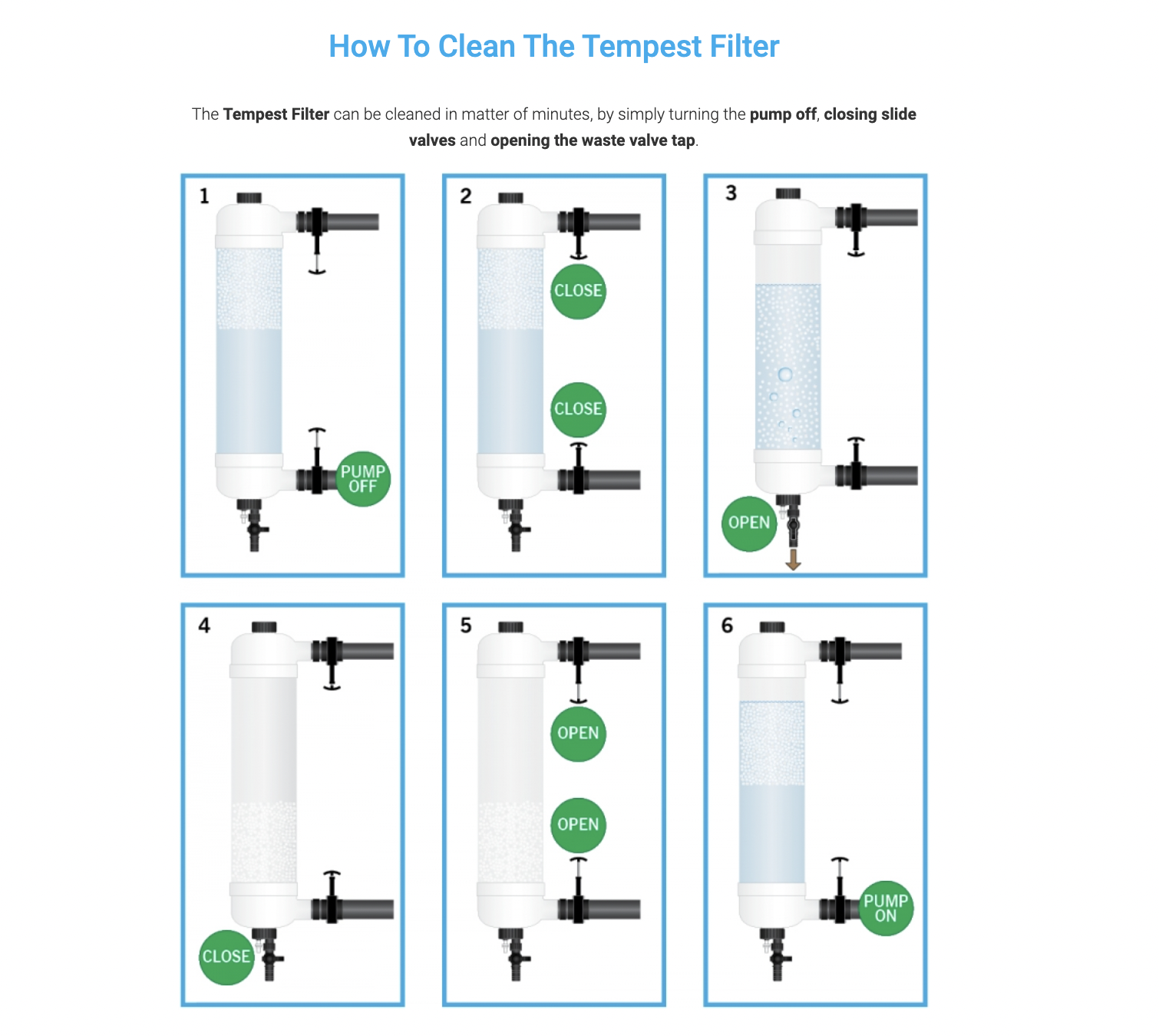

The Tempest filter is easy to install and is simple and quick to clean, by way of a unique, patent pending air syphon design. During the cleaning process, air is drawn into the filter as it empties which causes the water to agitate, effectively cleaning the K+Media.

- Additional Information

-